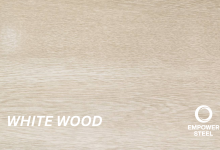

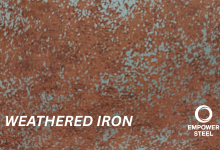

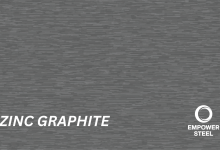

EM-UNIQUE™

Design Innovation

Resistance to Heat (Exposure Test)

Paint Adhesion Properties

(Cross Cut Test)

(Cross Cut Test)

Paint Adhesion Properties (T-Bend Test)

Resistance to Humidity (Cleveland Test)

Resistance to Corrosion (Salt Spray Test)

Resistance to Weathering (QUV Test)

Resistance to Colour Fading (QUV Test)

Resistance to Impact

(Reverse Impact test)

(Reverse Impact test)

Overview

EM-UNIQUE™ pattern painted steel utilises the most advanced manufacturing techniques to create unique patterns and virtual textures. Empower Steel’s advanced equipment can incorporate a variety of raw materials (Galvalume, Aluminium, Stainless) to coat multiple prints on the metal surface with the highest quality standards available. EM-UNIQUE™ meets AS/NZS2728 and other international standards.

Product Idea

EM-Strip™ clear film is designed to be used with Empower Steel products to prevent scratches whilst rollforming, transporting and during installation.

Substrate, Material Grade

: Galvalume Steel (AZ150, AM100, AM150) Galvanized Steel, Stainless Steel and Aluminium G550, G300

Surface Treatment

: Chemical Conversion Coating

Base Coat + Ink Coat + Clear Coat

: Paint system PVDF or Advance Durability Polyester 10 µm, Corrosion Inhibitive Primer 5 µm

: PVDF (Ink) or Advance Durability

Polyester (Ink) 3 µm

: High Durability Polyester 10 µm

: PVDF (Ink) or Advance Durability

Polyester (Ink) 3 µm

: High Durability Polyester 10 µm

Backing Coat

: Paint system Modified Polyester 5 µm,

Corrosion Inhibitive Primer 5 µm

Corrosion Inhibitive Primer 5 µm

Strippable Film

: Em-Strip Film

Base Metal Thickness (BMT)

: 0.2 – 1.2 BMT

Width

: 940 – 1270 mm

Testing Method

| Properties | Test Mehod | Purpose | Standard | |

| Dry film Thickness | Dry film Thickness Measurement | Paint Thickness | AS/NZS 2728 | |

| Paint Film Hardness | Pencil Hardness | Hardness properties of paint layer | AS/NZS 2728 | |

| Paint Adhesion | Cross Cut | Adhesion between paint layer | AS/NZS 2728 | |

| T-Bend | Colour adhesion and flexibility | AS/NZS 2728 | ||

| Dupont Impact | Colour adhesion and flexibility | AS/NZS 2728 | ||

| Reverse Impact | Colour adhesion and flexibility | AS/NZS 2728 | ||

| Gloss | 60º Gloss Meter | Colour gloss | AS/NZS 2728 | |

| Corrosion Resistance | Salt Spray Test (SST) | Corrosion resistant properties | AS/NZS 2728 |

More Testing Method

| Properties | Test Mehod | Purpose | Standard | |

| Weathering Resistance | ||||

| Chalking | QUV | Weather resistant properties | AS/NZS 2728 | |

| Colour Fading | QUV | Weather resistant properties | AS/NZS 2728 | |

| Humidity Resistance | QCT (Cleveland) | Relative humidity resistance properties | AS/NZS 2728 | |

| Solvent Resistance | Mechanical Rubbing (MEK) | Dryness of paint | AS/NZS 2728 | |

| Colour Shading | Light Source (Colour-Visual) | Colour difference | AS/NZS 2728 | |

| Colour Sectrophotometer (∆E) | Colour deviation | AS/NZS 2728 |

Product Warranty

- No peeling due to corrosion

- No flaking of colour

- The colour does not fade within the guaranteed period

Substrate, Material Grade

: Galvalume Steel (AZ150, AM100, AM150) Galvanized Steel, Stainless Steel and Aluminium G550, G300

Surface Treatment

: Chemical Conversion Coating

Base Coat + Ink Coat + Clear Coat

: Paint system PVDF or Advance Durability Polyester 10 µm, Corrosion Inhibitive Primer 5 µm

: PVDF (Ink) or Advance Durability

Polyester (Ink) 3 µm

: High Durability Polyester 10 µm

: PVDF (Ink) or Advance Durability

Polyester (Ink) 3 µm

: High Durability Polyester 10 µm

Backing Coat

: Paint system Modified Polyester 5 µm,

Corrosion Inhibitive Primer 5 µm

Corrosion Inhibitive Primer 5 µm

Strippable Film

: Em-Strip Film

Base Metal Thickness (BMT)

: 0.2 - 1.2 BMT

Width

: 940 - 1270 mm